BMTO TECH s.r.o.

BMTO TECH s.r.o. is a specialist in comprehensive supplies in the areas of CNC machining, sheet metal forming (laser cutting, water jet cutting, CNC bending), welding and 3D printing.

BMTO TECH s.r.o.

About Us

BMTO TECH s.r.o. was established by splitting off the production center of BMTO GROUP a.s., which has been operating stably on the market in the field of complex supplies for more than 35 years. The goal is to offer our customers a greater range of services, production flexibility and reliability of supplies. We specialize in custom production with the possibility of offering larger series thanks to the robotization of our workplaces.

We specialize in machining stainless steels.

BMTO TECH s.r.o.

Services

CNC Metalworking

We specialize in precise CNC machining of metals and plastics, offering turning, milling, drilling and threading for both individual and mass production.

Laser Cutting

We cut all metals up to a maximum material thickness of 20mm and with a table size of 3000 x 1500mm.

CNC Bending

We perform precise sheet metal bending on precise and rigid Durma AD-S presses with a bending length of 3000 mm and a maximum force of 170 tons.

Welding

We perform high-quality welding of steel, aluminum and stainless steel materials using various methods, including laser welding.

3D print and scan

We provide custom 3D printing from technical materials and 3D scanning of parts for easy digitization and prototype production.

We have a wide range of modern machines that allow us to respond flexibly to customer requirements.

We hold the following certificates: ČSN EN ISO 9001:2015, ISO 3834, ČSN 1090-2 EXC2, ČSN EN ISO 14001:2016

In cooperation with cooperation partners, we also provide:

- Galvanic plating (zinc plating, nickel plating, etc.)

- Blackening of steel

- Anodizing of aluminum

- Painting

- Thermal and chemical-thermal treatments

- Wire-cutting

01

CNC Metalworking

We produce precision CNC parts, focusing on both piece and series production.

We offer our customers CNC turning, drilling, milling and threading. We have TAJMAC, HYUNDAI WIA machines, with which we process various materials: steel, steel alloys, plastic and non-ferrous metals.

We use CAD/CAM software NX.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally a 3D model in STEP format), the required material, quantity, deadline and contact information for the person making the request.

We specialize in machining stainless steels.

02

Laser Cutting

We cut all metals up to a maximum material thickness of 20mm and with a table size of 3000 x 1500mm.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally a 3D model in STEP format), the required material, quantity, deadline and contact information for the person making the request.

03

Waterjet Cutting

We cut various materials (metals, plastics, wood, glass, ceramics, concrete, etc.) up to a maximum material thickness of 150mm and with a table size of 3000 x 1500mm.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally a 3D model in STEP format), the required material, quantity, deadline and contact information for the person making the request.

04

CNC Bending

We perform precise sheet metal bending on precise and rigid Durma AD-S presses with a bending length of 3000 mm and a maximum force of 170 tons.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally DXF format), type and thickness of the material, quantity, deadline and contact information for the person making the request.

05

Welding

We weld steel, aluminum. We specialize in stainless steel.

We use MMA, MIG, MAG, TIG, spot welding and laser welding. We hold ISO 3834 welding quality for class EXC2.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally a 3D model in STEP format), the required material, quantity, deadline and contact information for the person making the request.

06

3D print and scan

For the production of your prototypes, we offer custom 3D printing from a wide portfolio of materials – chemically resistant, with the addition of Kevlar, etc.

If you do not have a drawing of a machine part available, we are able to offer you 3D scanning services of the part.

We will be happy to prepare a price quote for you. Your request should include a drawing of the part (ideally DXF format), type and thickness of the material, quantity, deadline and contact information for the person making the request.

BMTO TECH s.r.o.

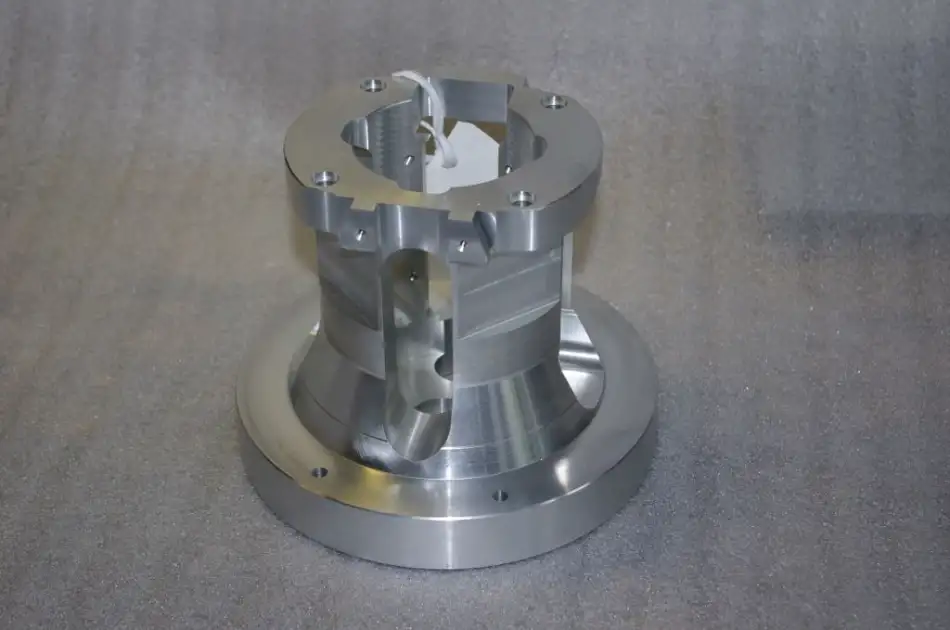

Photogallery

BMTO TECH s.r.o.

Contact

BMTO TECH s.r.o.

Ampérova 444, Liberec 23

463 12, Česká Republika

IČ: 04452411, DIČ: 04452411

Email: tech@bmto.cz

Phone: +420 485 382 338